Procedure of the EN 9100 Stage 1 audit

For an initial certification according to EN 9100:2018, a stage 1 audit (also: Stage 1 or Phase 1 audit) must precede the main audit. This is a mandatory pre-audit that is used to determine whether the company is basically prepared for the actual certification audit. This is a mandatory pre-audit that is used to determine whether the company is basically prepared for the actual certification audit.

The main part of the stage 1 audit is a document review. In preparation for the actual EN 9100 certification, the certification auditor gets an idea of the state of the QM system by inspecting the following documents and records:

- QM manual, process maps and process descriptions (which are usually requested by the auditor in advance of the audit).

- Quality metrics or key performance indicators for process measurement, as well as trend analyses that can be used to demonstrate process effectiveness.

- Customer Satisfaction Analysis,

- Records pertaining to the last management review,

- Internal audit reports for the last 12 months.

In addition, any non-applicable requirements (exclusions), including justification, must be defined and the scope of certification determined in the stage 1 audit at the latest. Last but not least, the auditor asks for the designation of an OASIS database administrator.

In the stage I audit, no audit findings are formulated, only so-called “Areas of Concern”. These deficiencies must then be corrected until the main audit. In this respect, this pre-audit should ideally take place two to four weeks before the main audit.

Find out now about our services for EN 9100

We support you with the accompaniment to the first certification as well as with audits and trainings.

Implementation of the EN 9100:2018 main audit

Every certification audit according to EN 9100:2018, be it the initial audit, the surveillance audit or the recertification audit, is always carried out in a structured manner, according to a defined procedure. The core components of any EN 9100 certification are

- the opening ,

- the audit execution,

- audit assessment and the creation of audit records, as well as

- the de-briefing.

Opening

The opening meeting is the beginning of the on-site audit process. The auditor first introduces his audit team – if available – and describes the certification assignment. In addition, the auditor explains the audit process on the basis of the audit plan, clarifies any ambiguities regarding the procedure and asks for approval or for the identification of any need for changes to the plan.

On the part of the company, the management, the QMB as well as any other QM employees involved and the most important representatives of the second hierarchy level should be present at the opening meeting.

Execution of an audit EN 9100:2018

The main objective of EN 9100 certification is to verify the compliance of operational processes with the requirements of EN 9100:2018, the customer, the legislator or its authorities, as well as the requirements of any interested parties. Important components that any audit must include are

- auditing of the processes according to the audit plan,

- A review and evaluation of the performance of the QM system, in particular continuous improvements, changes since the last audit, follow-up from previous audits,

- Review status of customer requirements (changes, new specifications),

- an evaluation of the process performance,

- Auditing of the procurement process,

- a review of customer satisfaction development and activities derived from this.

Each certification audit always includes an interview with the management. In it, the company must present its own self-awareness with regard to quality and customer orientation and be able to provide information on the current status of the performance of the QM system and on measures for continuous improvement.

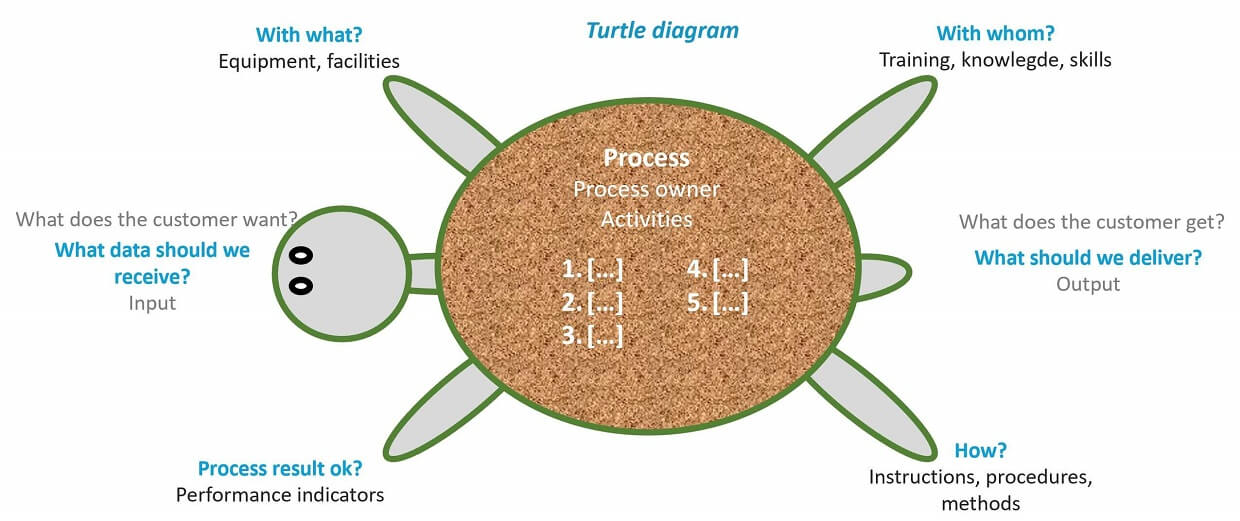

Another important element of certification audits according to EN 9100:2018 is the examination of the maturity level of process orientation, including an evaluation of process performance and effectiveness. A helpful way to determine the completeness of just the core processes is to use a Turtle Diagram as shown. At the same time, these help the certification auditor fill out the PEAR forms.

Do you need support in the EN 9100 environment?

We support you!

Get a non-binding offer at or

+49 (0)40 5131 5291

Companies must meet a plethora of requirements at all operational levels. Companies do not always succeed in implementing all the required specifications in their day-to-day operations. It is an essential task of an EN 9100 certification to identify such non-conformities. These have the same severity, so there are the following classifications:

- major non-conformity (also: serious or major finding),

- minor non-conformity (small or minor finding),

- Recommendation / opportunity for improvement (OFI).

A major non-conformity exists if it must be assumed that the non-fulfillment of a requirement would 1.) leads to failure of important components of the QM system, 2.) in case of the product or service defects or if there is risk of shipping a non-conforming product, or 3.) if the non-conformity is expected to have a noticeable effect on the customer by limiting the usability of the service or product.

A minor nonconformity exists when there is noncompliance with a requirement, but it does not warrant a major nonconformity. These are therefore singularly occurring errors or the non-conformity of individual requirements without substantial or lasting influence on the QM system, on the processes or on the product or service.

Do you already know our EN 9100 E-Learning?

- 180 Minutes

- Video animated clips with sound

- Certificate is sent automatically after passing the test

- Saves working time compared to 1-day face-to-face training

- Structure analogous to the standard

Dealing with audit findings

Audit findings are processed electronically in the OASIS database in a Non-Conformity Report (NCR). For this purpose, the auditor creates a separate NCR for each non-conformity during the certification audit and fills in the basic data in the NCR. There, the auditor describes, among other things, the finding, names the associated objective evidence as well as the EN 9100 requirement that was not met. Finally, the auditor classifies the non-conformity as Major or Minor.

Following the audit, it is the responsibility of the organization to identify the root cause of the finding and to derive and implement measures and document them in OASIS. By the way, the causes are to be eliminated and not the symptoms. At least in the case of serious finding, a methodologically sound procedure (e.g. 5W method) is required. It needs to shows that the deeper causes of errors have also been identified. Subsequently, the NCR must be reported back to the auditor via the OASIS workflow.

Only when all audit findings have been correctly processed and reported back via NCR may the auditor recommend to his certification body that the certificate be issued or extended and the certificate be issued in accordance with EN 9100:2018. This completes the process of EN 9100 certification.

Our Books

Do you already know our books on technical aviation management?